CubeSat and SmallSat

Enabling mission success by maximizing the stowed footprint

CTD has unique experience in designing novel composites that underpin the ability for CubeSat and SmallSat operators to deploy large and complex booms, arrays, and panels from minimum stowed volumes. The key to creating unique configurations for reflector antennas, booms, and arrays results from harnessing the material properties to unfurl the stowed structure in an efficient and controlled manner. CTD’s unique material properties coupled with the expertise of our team of aerospace and mechanical engineers deliver capability well beyond the envelope.

Our decades of experience in traditional space enable us to quickly align to this New Space paradigm where cost and functionality deliver Space to masses at a fraction of the cost. Inevitably, the data that your mission collects will only be as good as the instruments and structures performing the collection. Whether you need to optimize boom-length to create separation from the satellite, or your structural frequencies demand a rigid structure capable of bearing the load, CTD understands those challenges and trade-offs and will be the enabling capability for your mission critical hardware.

Contact us and we will be happy to leverage our solutions to meet your mission needs!

CLASP

(Composite Lightweight Array with Shape-memory Polymer)

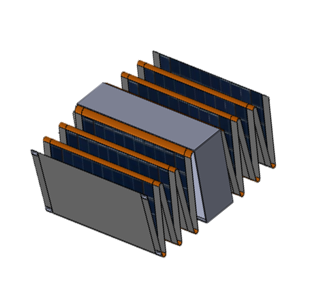

CTD CLASP (stowed)

CLASP 6U

Specific Power: 250 W/kg

Packaging Efficiency: 110 kW/m3

Total power: > 200 W

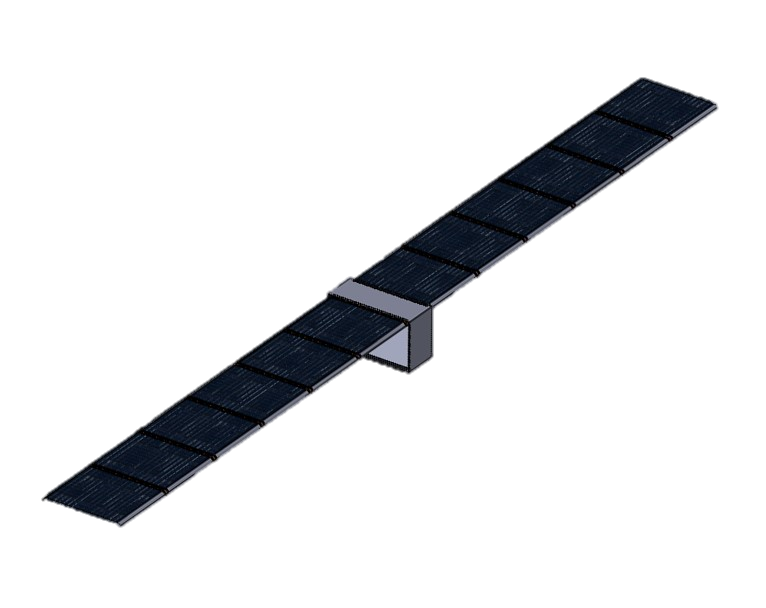

CTD CLASP (deployed)

The most efficient packaging and deployment performance architecture for spacecraft solar power generation

Over 250 W/kg delivers more power for your mission than existing solutions

Highest packaging efficiency of any solar power solution, enabling better instrumentation on your spacecraft which leads to better data.

Ideal solution for constellations as you can fit more satellites in the launch vehicle, reducing your overall launch costs.

CTD Booms and Deployers

CTD manufactures high-strain composite booms and boom deployer mechanisms. These systems span CubeSat to LargeSat scales. The high-strain composite material can be flattened and rolled for efficient stowage and unfurl to form long tubular members. CTD’s boom & deployer mechanisms can be customized for integration into a wide range of deployable systems. CTD’s patented Slit-Lock™ booms have interlocking teeth along the seam resulting in superior torsional and bending stiffness.

Key features of CTD’s CubeSat boom and deployer systems include:

- Overlapping slit-tube booms, or patented Slit-Lock™ options available

- Carbon fiber composite and/or fiberglass composite boom substrates

- Hybrid metal-composite booms available with outer metal layers up to approximately 0.0005 inches thick for antenna applications

- Root-Lock™ mechanism for clamping of a boom at its root when fully deployed to achieve superior deployed stiffness and high first-mode frequency.

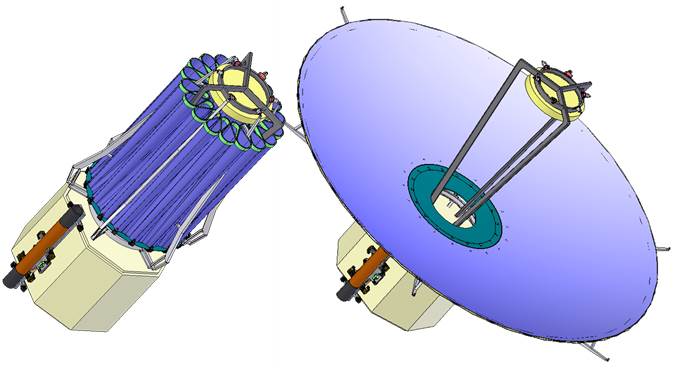

TEMBO® Antenna Reflectors

CTD-developed composite materials enable unparalleled stowing capabilities for satellite and space-based deployable communications antennae. CTD’s TEMBO® composite material enables packaging of carbon fiber composite reflector shells into small packages that are deployed once the payload reaches orbit. The novel composite material used in TEMBO® reflectors eliminates the need for any heavy mechanical deploying subsystems. The TEMBO® composite material only requires the application of heat through integrated, structural heaters to deploy the system. The reflector deployment is smooth and damped. This packaging and deployment approach (US Patent 7,710,348) enables small, inexpensive spacecraft to employ large antenna reflectors for high-gain RF missions such as RADAR, SAR, COMMS, and SIGINT. Additionally, this reflector design uses integral reflector stiffeners fabricated with shape memory polymer (US patent 7,897,225).